10 Things to Know when Choosing Access Panels for Your Project

For more than 25 years, BAUCO has been designing and manufacturing architectural access panels for drywall walls and ceilings. Last year alone, we shipped over 60,000 access panels to job sites across North America, Central America, and the Caribbean—each one meeting the unique demands of different projects.We know that no two projects are the same, and finding the right access panel solution requires careful consideration. That’s why we’ve put together a list of 10 things to know when choosing access panels for your project:

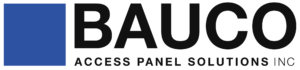

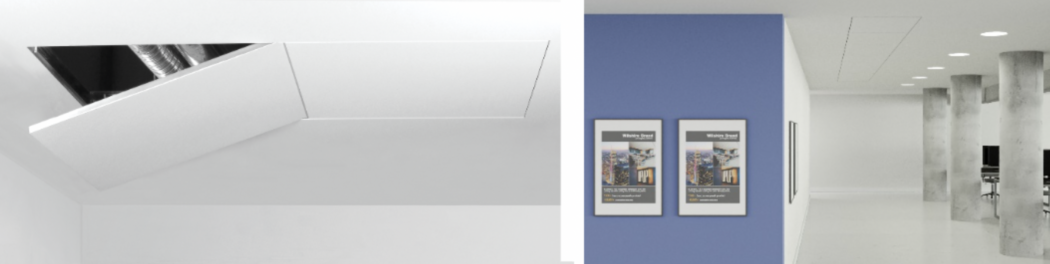

- Panel Location: Will the access panel will be installed in a wall or ceiling? Location influences the type and design of the panel. Choosing the right model and/or the right hardware options can improve function and fit for your location

- Compliance with Building Codes and Standards: Ensure the panel meets local building codes and regulations. Assess if the installation area necessitates a fire-rated access panel to comply with safety regulations. Perhaps there is acoustic or other standards to be met. Does the building inspector require access to emergency shut-off valves, clean-outs, and fire dampers? Are you dealing with a clean room environment?

- Aesthetic and Design: Does the panel need to be virtually invisible? What are the finishing requirements such as paint, wallpaper, plaster, tile or wood cladding? Consider alignment of sightlines with other architectural features and size the opening accordingly. One custom sized panel results in much less visual clutter then two or more scattered access panels. Fit the access panel to the tile grout lines.

- Size and Dimensions: Consider the size of opening needed for maintenance or access to utilities behind the panel. Is it for hand access and visual inspection only, or does equipment of a certain size need to pass through? Measure the rough opening and order the panel to fit, or create the correct rough opening for the desired access opening size. Order custom sizes and shapes for non-standard openings. Consider the height/clearance in the wall or plenum cavity needed to accommodate the access panel’s frame and hardware.

- Material Selection: Choose materials that match the environmental conditions and desired durability, such as galvanized and/or powder-coated steel or aluminum for corrosion resistance. Consider materials with mold and moisture resistance for high-humidity environments.

- Security: Determine the level of security required. Consider standard concealed touch latches, flush cam latches with tamper-resistant torx head, or choose flush key lock.

- Acoustic Performance: If sound transmission is a concern, select panels designed and tested for acoustic integrity to maintain sound transmission standards. Access panels with drywall inlays and gaskets perform better acoustically. Custom options may further improve performance.

- Air Tightness: For areas requiring limits to air flow, select panels with EPDM rubber gaskets to ensure an airtight seal. Review manufacturers independent test results for air tightness.

- Ease of Installation: Review the installation instructions, videos and framing requirements to ensure installation requirements are clear. Call one of our technical consultants to answer any questions you may have.

- Customization Needs: Identify any special requirements to accommodate specific project demands. This could include the orientation or hinging (left/right swing or long side/short side hinged), hardware configurations (structural bracing, latches, installation aides), or changes to accommodate specific surface treatments (plaster, wood, tile). You may want to choose the Paint-ready option applied at the factory to save on-site trades time.

Ready to learn more? Visit our Product Selector page to compare models and find the right solution for your project’s needs.